How to Mash Beer Brewing YouTube

Is a Mash Out Necessary in Home Brewing? Pros & Cons

Namely because the sparge to boil time is fairly quick. Compared to what may take much longer when brewing at the 7bbl or more level. Mashing out will lock in the mash profile you have achieved during the mash. Despite a positive test with iodine, there can still be some complex sugar/starch molecules remaining that will continue to convert if.

Pin by Robert Gollwitzer on Favorite TV Shows Mash characters, Mash

Whether you are looking for a way to tweak mash enzyme activity, understand a bit more about brewing calculations surrounding mash and sparge water needs, determine mash volume, calculate strike water temperature, or figure out how much mash to boil for a decoction, mash thickness is a vital part of the conversation.

Sour Mash Whiskey What is it and how is it made? Gentlemen Ranters

A mash-out is the part of the brewing process where the temperature must be raised to start your sparge. A high temperature of anywhere from 167 degrees F to 170 degrees F is necessary to help your brew slow down, turning starches to sugar. This step will help you stop the enzymatic conversion of starches to sugars, which will ultimately make.

Broccoli Mash Online Discounts, Save 54 jlcatj.gob.mx

Mash out is a step in the brewing process used to stabilize the mash and improve the wort's clarity. Brewers achieve this by raising the mash temperature to 170-180 Fahrenheit for 90 minutes before lautering. The elevated temperature helps to gelatinize the starch in the malt, making it easier to extract sugars during boiling.

What Is Mash Out? Beer Snobs

A mash out, put simply is a method of raising the temperature of the mash just before the sparge is started. Usually, the temperature of the mash is raised to around 75-77°C (167-170°F) or thereabouts which does a few things. First off, all the activity of the enzymes working at converting starches to sugars is halted as the temperature.

MashBills_1 Mash bill, Distillery, Distilling alcohol

Mash out is the process of raising the temperature of the mash to around 170°F (77°C). 2. The main objective of mash out is to stop enzymatic activity and make the grain bed more fluid. 3. By raising the temperature to 170°F, the enzymes that convert the starches into fermentable sugars are deactivated. 4.

Mash Chemistry 101 Distiller Magazine

The Purpose of Mashing. Mashing is, in its most simple form, a process that breaks longer carbohydrate molecule chains into simpler sugars that can be fermented. Yeast most readily consumes simple sugars like maltose and glucose, and mashing creates the simple sugars yeast needs to ferment and produce alcohol in a finished beer.

Mash Brewing The Crafty Pint

For neutral beers, we split the difference. We have common mashing times with the above mashing temperatures listed below. Mash at 148 degrees for 75 minutes for a drier beer. Mash at 152 degrees for 60 minutes for a neutral beer. Mash at 156 degrees for 40 minutes for a fuller beer.

A look back on enduring appeal of "M*A*S*H," 40 years after final

Mashing out is the term given to the act of boosting your mash temperature prior to running off your wort. For many brewers, a single infusion mash is what they use. This post will discuss if performing a mash out step is worth it. In some mashing setups, adding heat to either the wort or mash is easy. When you mash in an insulated vessel with.

Pig Feed 14 Mash Pierce Milling Inc.

The mash-out indicates an advanced brewing position and may be undertaken if the brewer has reached that level. In any situation it is time-consuming and for 5 - 10 gallons of beer, it simply may not matter: if the sparge water temperature is accurate and held in an insulated vessel. The pros and cons balance out.

various mash temperatures overlaid graphically Home brewing beer

Mashing involves soaking crushed grains in warm water for 60 - 90 minutes, also known as steeping. The purpose of the mash is to allow the enzymes to convert the starches in the grains into sugars that the yeast can ferment; whereas a mash-out stops the conversion process. When performed correctly mashing allows the brewer to produce a wort.

How to Mash Beer Brewing YouTube

Put a hose on the outlet for your mash tun, crack the valve just a bit and allow your wort to trickle out into your pitcher. Hot swap the empty in when the first pitcher is about half full or so. While pitcher 2 is filling slowly, pour the contents of pitcher 1 back into the mash tun. A key point to recirculation is not disrupting the grain bed.

What Is Mash Out? Beer Snobs

The mash out step stops all of the enzymatic action (preserving your fermentation sugar profile). But as the Grainfather brewing units ramp up to near boil as soon as the sparge has started and you sparge with 75°C (167°F) water, the enzymes will be denatured. So it is good to ramp up to this temp before starting the sparge but this step can.

Sausage and mash recipe BBC Food

Mash out. Because it takes time to raise the temperature using direct heat, the process actually looks like this: Step Mash Schedule - winningbeers.com. A short beta glucan rest at 40ºC helps dissolve the starches, but it takes a while to raise the temperature to the next rest.

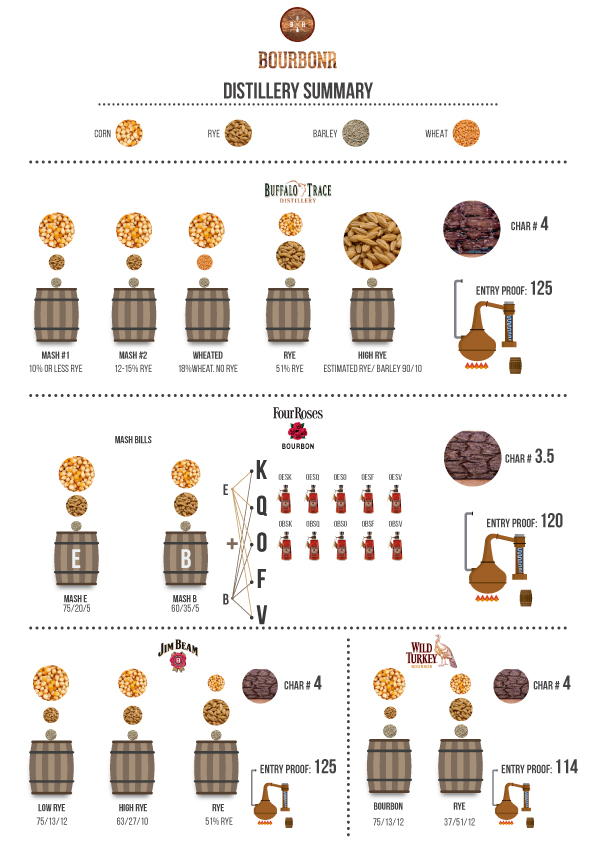

Updated Buffalo Trace Distillery Mash Bills Blog Bourbon Whiskey

What it is. Vorlauf is German for "first runnings," and is now used as both a noun and verb to describe the overall process. In all-grain brewing, it's the second step in the process of lautering, following mash-out. At this point you're preparing your wort for the boil, and the vorlauf step accomplishes two valuable goals: setting the grain.

"Mash Out Posse" Poster for Sale by StrictlyDesigns Redbubble

A "mash out" is a step in which the grains are heated, by direct heat or by adding hot water, to 168-170F after the mash. For most mashes with a ratio of 1.5 - 2 quarts of water per pound of grain, the mash out is not needed. (There are more complex mash programs, such as step mashing and decoction, but partial mash recipes rarely call for these.