Can Withstand Heat Stanford

Can Withstand Heat Stanford

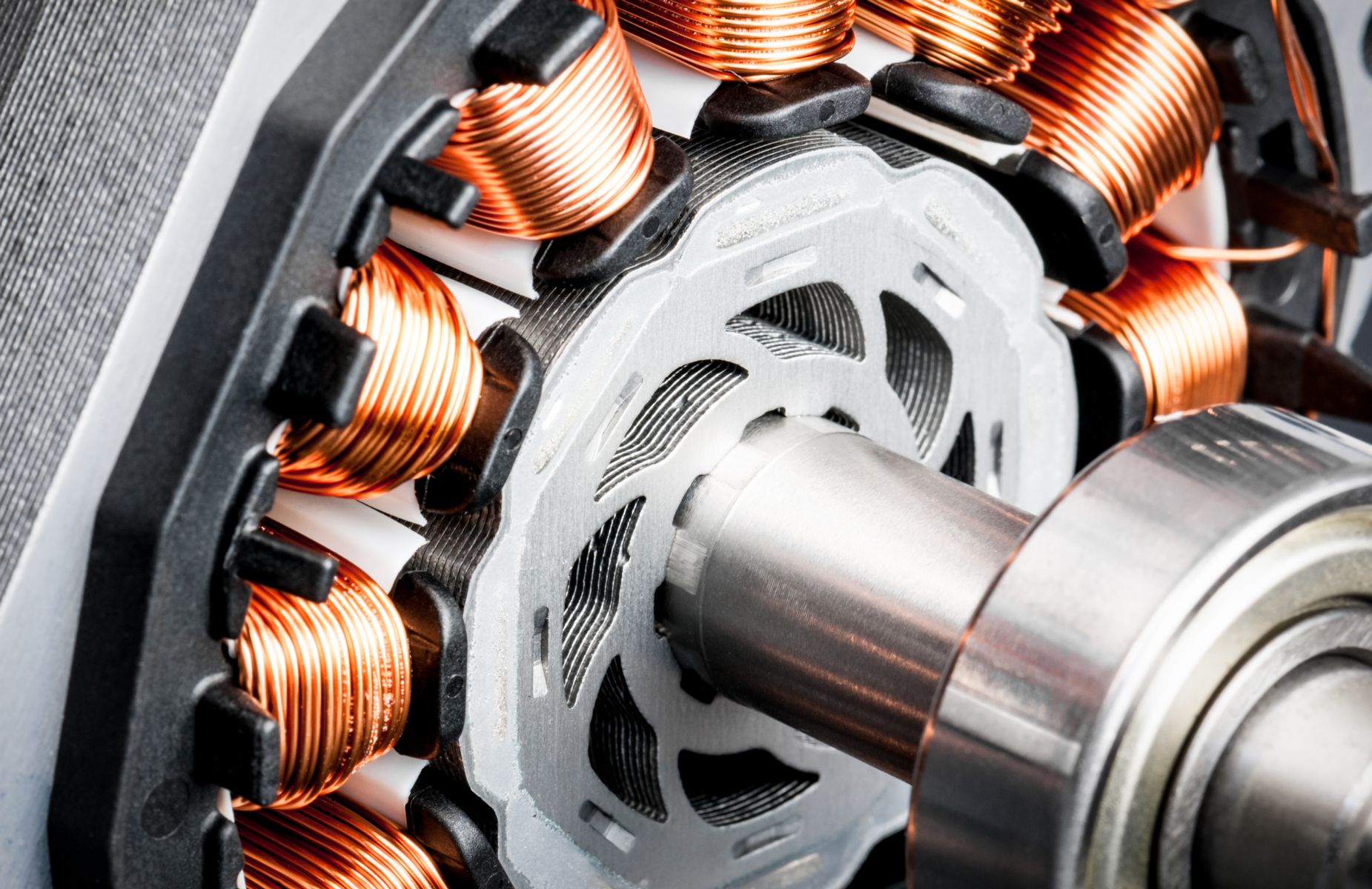

This work addresses the problem of mitigating the effects of the cogging torque in permanent magnet synchronous motors, particularly brushless motors, which is a main issue in precision electric.

X1401 4 POLE BRUSHLESS MOTOR

What glue do you recomment for the motor magnet? One of the magnet of my BL motor went off. Still want to save this. Epoxy steel? Super glue?. I will check on Monday when I am at work. If its good enough for a 500 mm dia brushless motor, the magnets are 120 mm x 70 mm x 20 mm. Sep 14, 2015, 06:06 AM #10; DYORD. DYORD. Registered User. Thread OP.

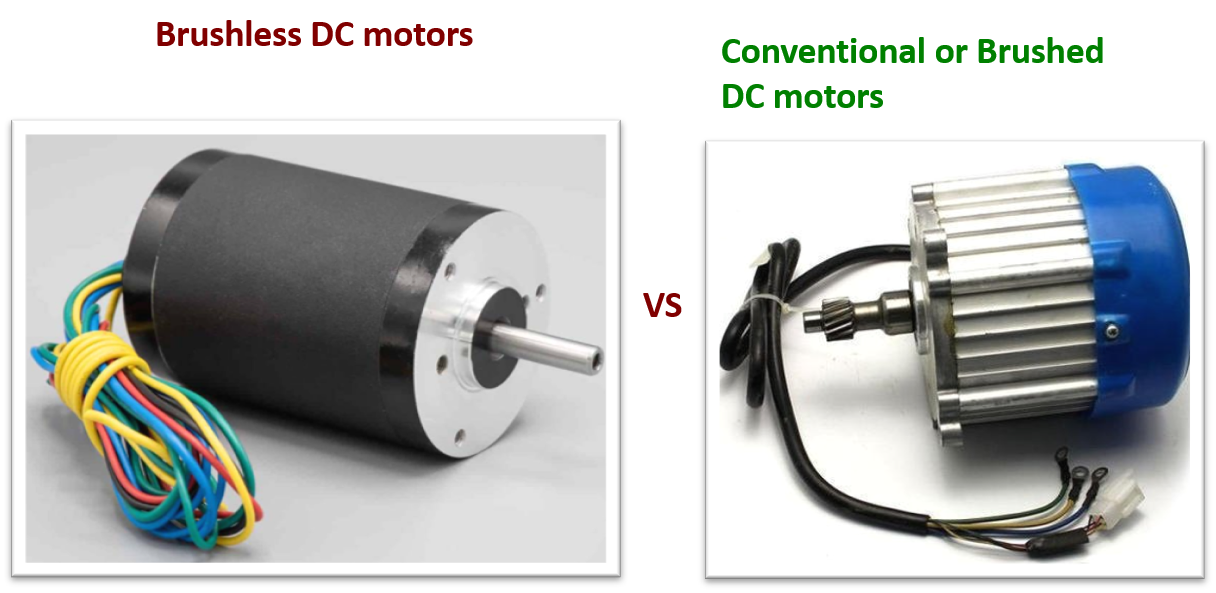

Mikro Pendel Religiös dc motor brushed vs brushless Ehrlich rotes Datum Abkürzen

Upgrade/Replace Brushless Motor Magnets By Jaronv in Circuits Electronics 24,931 171 21 Featured Download I have salvaged quite some motors from old printers and used them for various projects, but these usually use inferior ferrite magnets (Like those flexible fridge magnets). They are not very strong so the motor strength is limited.

Brushless DCServomotors 2 pole technology, sensorless

Just glue the magnets back in place using thick CA or epoxy. Pay attention to polarity, the sequence should be N-S-N-S etc. You can use any household magnet to check that each other motor magnet attracts it and those in between repel it. Apr 25, 2017, 09:30 AM. #3. Ron van Sommeren. Ron van Sommeren.

Developing electric motors less dependable on rare earth Automotive IQ

Brushless motors in your car or plane take a pretty hard beating and it's not uncommon to see a motor throw a magnet. In this article we discuss how to fix it and get back on the road or into the sky the easy way. Sure, you could buy a new motor but it might be quicker to fix the one you have.

Buy Genmitsu CNC Brushless Motor DC Spindle Kit 24V 12000rpm with Drive Board & Collet Holder

How to Glue Brushless Motor Magnets - When building models, be they planes or boats or robots, the ubiquitous motor of choice is the brushless motor. The reason for this is power and longer run times. A motor with brushes has current running through them into the center of the motor.

Brushless DC Motor Design GUAN MING SINGAPORE PTE LTD

About Press Copyright Contact us Creators Advertise Developers Terms Privacy Policy & Safety How YouTube works Test new features NFL Sunday Ticket Press Copyright.

18N20P DC24V 100W disc permanent three phase brushless DC motor / motor diy feels with

BRUSHLESS MOTOR: MAGNETS FIXING AND PROTECTION - HEAT SHRINK TUBING POLITUBES : EASY, QUICK AND AUTOMATIC SOLUTION TO HEAT SHRINK OUR TUBES ONTO BLDC ROTORS Watch on SOLUTION FOR FIXING AND PROTECTING PERMANENT MAGNETS IN BRUSHLESS MOTORS

20V Cordless Stick Vacuum Kit w/ Brushless Motor Technology HART Tools

For a permanent repair all the magnets would be removed, the inside of the flux ring cleaned of all the old glue, and then re-gluing all of them with a batter adhesive would be in order. As far as the better adhesive, the debate rages here. Some like epoxy, some like JB-weld, and others use various CA adhesives.

Dini kaynak aşma brushless motor eğlendirmek dalga Cevap vermek

Animation showing operation of a brushed DC electric motor. An electric motor is an electrical machine that converts electrical energy into mechanical energy.Most electric motors operate through the interaction between the motor's magnetic field and electric current in a wire winding to generate force in the form of torque applied on the motor's shaft. An electric generator is mechanically.

DAV Tech Electric motors gluing

Politubes enlarges its range of heat shrink tubes for brushless motors (SPM surface permanent magnets), with a the new generation of Class F- H, B-Stage epoxy resin coated tubes in order to achieve a solid bonding to the rotors.. Cure the glue between magnets and rotors. Activate epoxy resin inside our tubes for a perfect bonding. Heat.

An Introduction to Brushless DC Motors

How to Glue Brushless Motor Magnets 2013-05-31. When building models, be they planes or boats or robots, the ubiquitous motor of choice is the brushless motor. The reason for this is power and longer run times. A motor with brushes has current running through them into the center of the motor. After a time, friction can cause wear, resulting in.

X1401L 4 POLE BRUSHLESS MOTOR

How to make a big permanent magnet rotor for Brushless motor or GeneratorMagnet 20x10x5mm https://bit.ly/2zQlyeD-----.

Brushless Coreless Motor

How to Fix Loose Magnets in Brushless Motors Early NTM motors had a reputation for throwing magnets however the later variants in the Turnigy Propdrive range are bulletproof with better performance, finish, and fittings than the first generation.

Brushless Motor 2200KV QXMOTOR

In certain situations, magnets in brushless motors may become loose due to crashes or vibrations. Loose magnets can negatively impact motor performance and reliability. To address this issue, it is possible to use adhesive solutions like Loctite 438 to secure the magnets back in place within the motor bell. This helps ensure proper alignment.

New 388VF 630N.m Max Brushless Impact Wrench Liion Battery Brushless Motor Electric Wrench

Also used CA once in the past. Fine for low power, but high power or more rightly heat, made the CA let go. Loctite generally lets go with high heat too, but higher than the mags should be exposed to. I keep mine below 60degrees if I can, 80 max, and the loctite holds up.